Additive manufacturing makes the Mako a scalable, cost-effective hypersonic weapon that allows for salvo fires, unlike weapons such as the Russian Kh-47M2 Kinzhal or the US’s AGM-183 ARRW.

The hallmarks of Lockheed Martin’s Mako hypersonic missile revolve around being modular and mass-producible, aided by additive manufacturing (commonly known as 3D-printing), allowing these high-speed munitions to be scaled and rapidly integrated onto nearly every U.S. airborne fighter, attack and bomber platform. The company has outlined these features in a new promotional video on the missile, three months after it was first unveiled.

The Mako can be carried internally by the U.S. Air Force’s F-35A, the U.S. Navy’s F-35C, and other fourth generation fighters like the F/A-18 Super Hornet, the F-15, F-16 and even the P-8A Poseidon maritime patrol and reconnaissance aircraft. Lockheed Martin says the weapon has been fit checked on these aircraft to verify they can carry it.

Basically, Mako is compatible with any aircraft that can carry the BRU-32 heavy duty ejector racks.While Mako can be carried internally by the F-35A and F-35C, it cannot be carried in the weapons bay of the F-35B because of its smaller size, owing to the large vertical lift fan. However, the F-35B, like the other two variants, can still carry Mako externally on its underwing hardpoints, in missions where stealth is not a priority.

Differentiated by manufacturing processes

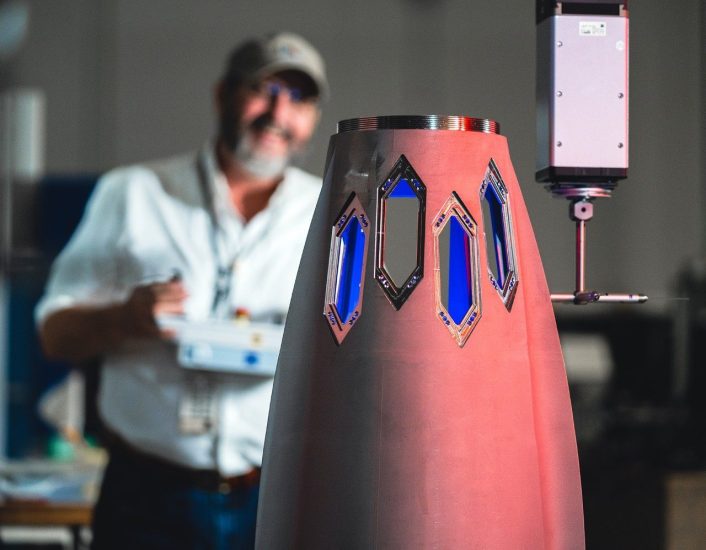

What makes the weapon stand apart, according to the video by Lockheed Martin, is the additive manufacturing process the company has adopted for the production to make several of its parts, such as guidance housing and fins. Footage of the industrial process also shows the highly automated production of these two parts.

“Engineers used additive manufacturing to produce the guidance section and fins,” mentions the video. “The additive guidance section meets all engineering requirements at 1/10th cost and it’s 10 times faster and cheaper than conventional subtractive methods.”

This significantly cuts down costs, beside the modular, open systems architecture that allows for quick upgrades, switching sections like guidance or seekers depending on the mission requirements. Lockheed Martin says that these elements can be upgraded with “no proprietary entanglements,” means other defense firms and contractors can undertake the modifications chosen by the U.S. military.

Mako evolved from Lockheed’s innovation and maturation efforts invested in the U.S. Air Force’s SiAW (Stand-in Attack Weapon), where the company chose not to continue into the program’s phase 2. To lower risk and cost, Mako incorporates components from fielded systems and proven supply chains. All subsystems are customer-validated as mature, with a technical readiness level 6 or higher, says the company.

Mako is among Lockheed Martin’s “first generation of missiles designed entirely in a digital engineering ecosystem.” The model-based systems engineering approach and an integrated, model-based enterprise support the life cycle of the weapon, as the company mentions it has been digitally developed with producibility in mind, with manufacturing engineers in the loop from the start to ensure a seamless transition into production.

Possible tactics

The characteristics of Mako make it a rare, scalable and cost-effective hypersonic weapon that allows for salvo fires, unlike weapons such as the Russian Kh-47M2 Kinzhal or the US’s AGM-183 ARRW (Air-Launched Rapid Response Weapon). These single shot weapons need to be used sparingly, owing to their prohibitive price tags, while Mako “puts air-launched hypersonic mass on critical targets at operationally significant ranges.”

While it must be noted that the system is not yet a PoR (Program of Record), formally noted in defense budget documents which guarantees a certain amount of funding, there is a possibility that the USN might try to divert to it any surplus money, depending upon the progress of its other programs.

Nevertheless, it would be important to look at possible tactics and employment practices that might guide Mako’s use. For one, its development comes in the backdrop of Lockheed Martin revealing its proposal to develop the existing Sniper ATP (Advanced Targeting Pod) into the Sniper Networked and Targeting Pod.

As The Aviationist reported, the new system would combine the Sniper’s current targeting and reconnaissance capabilities with a networking capability, allowing advanced secure datalinking between not only fourth generation and fifth generation aircraft, but also with ground forces, such as HIMARS and M270 MLRS. This brings some of the F-35’s pioneering networking capabilities to Generation 4 and 4.5 fighter-bombers, where the latter could function as “missile trucks,” releasing air-to-ground munitions on targets identified by the F-35.

Meet Mako™, our new multi-mission hypersonic missile that launches from 4th and 5th-gen fighters.

— Lockheed Martin (@LockheedMartin) July 24, 2024

One of these missiles could be Mako, allowing time-sensitive targets in rapidly evolving, fluid battlefield situations to be engaged faster by exploiting the weapon’s high-speed. In China’s case, the targets could be their networked IADS (Integrated Air Defense Systems) or PLA Navy destroyers posing targeting dilemmas to American CBGs (Carrier Battle Groups).

Radar emissions detected by the F-35’s superior ELINT (Electronic Intelligence) sensors could be beamed to the ATP and Mako-equipped F-15EX Eagle IIs or E/A-18G Growlers, which could release volleys of hypersonic weapons. The F-35s would themselves constitute a penetrating first wave, acting as stealth and jamming-capable airborne tactical electronic, optical, radar reconnaissance and networking posts.